New Products

Find Pelletizer Production Line, Twin Screw Plastic Granulator, Plastic Pelletizer Machine on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

| Payment Type: | L/C,T/T,Western Union |

|---|---|

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 30 Days |

Model No.: KTE-75B

End products

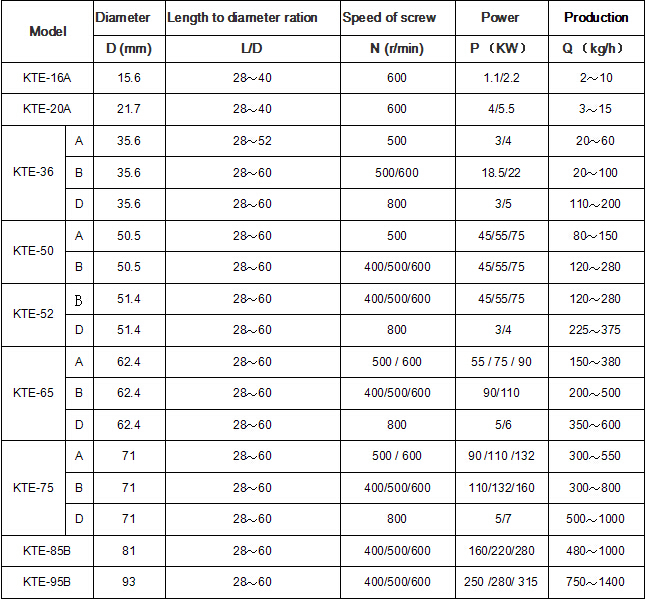

End products  Technical Parameters of twin-screw PET recycling masterbatch granulator machine :

Technical Parameters of twin-screw PET recycling masterbatch granulator machine :  Representative materials working capability schedule of KTE-series same-direction parallel twin-screw plastic recycling extruder(granulator/pelletizer):

Representative materials working capability schedule of KTE-series same-direction parallel twin-screw plastic recycling extruder(granulator/pelletizer):  advantages: >>This structure can afford a high speed to guarantee highly efficiency >>Easy maintenance >>Its self-cleaning can improve products quality and easy to clean. >>building blocks barrel and screw can afford your variety requirements Certifications

advantages: >>This structure can afford a high speed to guarantee highly efficiency >>Easy maintenance >>Its self-cleaning can improve products quality and easy to clean. >>building blocks barrel and screw can afford your variety requirements Certifications  Spare parts of twin-screw PET recycling masterbatch granulator machine :

Spare parts of twin-screw PET recycling masterbatch granulator machine : 2.the feeding systerm Various forms of feeding structure and system single screw extruder, twin screw, hollow spring type, mesh and mesh, can cover the various material status

2.the feeding systerm Various forms of feeding structure and system single screw extruder, twin screw, hollow spring type, mesh and mesh, can cover the various material status  3.screw and barrels Screw Kneading block built on modular principle allows various L/D ratio of screw easily be changed to suit different material. Screw component made of high speed & wear-resisting steel. The screw elements are designed accuratly and made of high tool steel 38CrMoALA or W6Mo5Cr4V2 by special heater treatment.

3.screw and barrels Screw Kneading block built on modular principle allows various L/D ratio of screw easily be changed to suit different material. Screw component made of high speed & wear-resisting steel. The screw elements are designed accuratly and made of high tool steel 38CrMoALA or W6Mo5Cr4V2 by special heater treatment.  end products

end products  Company Information Nanjing Kerke Extrusion Equipment Co., Ltd is a comprehensive manufacturing and trading company in China. our company is a professional manufacturer of high quality pelletizing extruders for coloring /dyeing and masterbatch production, as well as plastic modification and compounding,plastic recycling. Innovative machines are built as per the concept of durability, high efficiency and economical power consumption. We carry out a strict quality management system in accordance with CE requirements. There are over 100 styles of extruder and extruder spare parts and we also can customize for customers' various requirement for extruder spare parts. Our annual production capacity is 200 sets plastic extruder in domestic country! And we also have OEM ability in pelletizing plastic extruder industry in consistence with specific requirement from both national and international customers. Moreover, we are pleased to introduce our company as one of the leading exporters of parallel twin screw extruder in China. Our machine types: 1. Co-Rotating Parallel Twin Screw Pelletizing Extruders

Company Information Nanjing Kerke Extrusion Equipment Co., Ltd is a comprehensive manufacturing and trading company in China. our company is a professional manufacturer of high quality pelletizing extruders for coloring /dyeing and masterbatch production, as well as plastic modification and compounding,plastic recycling. Innovative machines are built as per the concept of durability, high efficiency and economical power consumption. We carry out a strict quality management system in accordance with CE requirements. There are over 100 styles of extruder and extruder spare parts and we also can customize for customers' various requirement for extruder spare parts. Our annual production capacity is 200 sets plastic extruder in domestic country! And we also have OEM ability in pelletizing plastic extruder industry in consistence with specific requirement from both national and international customers. Moreover, we are pleased to introduce our company as one of the leading exporters of parallel twin screw extruder in China. Our machine types: 1. Co-Rotating Parallel Twin Screw Pelletizing Extruders Business attitude (1) ALL of our products are of high quality with good apperance

Business attitude (1) ALL of our products are of high quality with good apperance  (2) We actively take part in exhibitions

(2) We actively take part in exhibitions  If you interested in our products mentioned above. Kindly let us know by return email! We can provide you the most professional advice according to your demands! Also we can make non-standard plastic machinery as customer’s requirements!

If you interested in our products mentioned above. Kindly let us know by return email! We can provide you the most professional advice according to your demands! Also we can make non-standard plastic machinery as customer’s requirements!

Product Categories : Underwater cutting Pelletizer