New Products

Find Two Stage Compounding Extruder, High Quality Two Stage Compounding Extruder, Two Stage Compounding Extruder Details on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

| Payment Type: | L/C,T/T |

|---|---|

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 40 Days |

Model No.: SHJS75/180

Model | Screw Dia D (mm) | L/D Ratio | Screw speed N (r/min) | Motor power P (KW) | output Q (kg/h) | |

SHJS50/100 | SHJ50 | 50.5 | 24~48 | 500 | 37 / 45 | 100~350 |

SJ100 | 100 | 7~20 | 85 | 30 / 37 | ||

SHJS65/150 | SHJ65 | 62.4 | 24~48 | 500 | 55 / 75 | 200~500 |

SJ150 | 150 | 7~20 | 85 | 37 / 45 | ||

SHJS75/180 | SHJ75 | 71 | 24~48 | 500 | 90 / 110 | 400~800 |

SJ180 | 180 | 7~20 | 85 | 45 / 55 | ||

SHJS95/200 | SHJ95 | 93 | 24~48 | 400 | 200 / 250 | 700~1500 |

SJ200 | 200 | 7~20 | 85 | 55 / 75 | ||

Twin-screw extruder

Twin-screw extruder  Single-screw extruder

Single-screw extruder  Air-cooling hot-face pelletizer

Air-cooling hot-face pelletizer  Hydraulic screen changer

Hydraulic screen changer  cyclone End products(wpc granules)

cyclone End products(wpc granules)  Packing and shippment

Packing and shippment Our professional workers

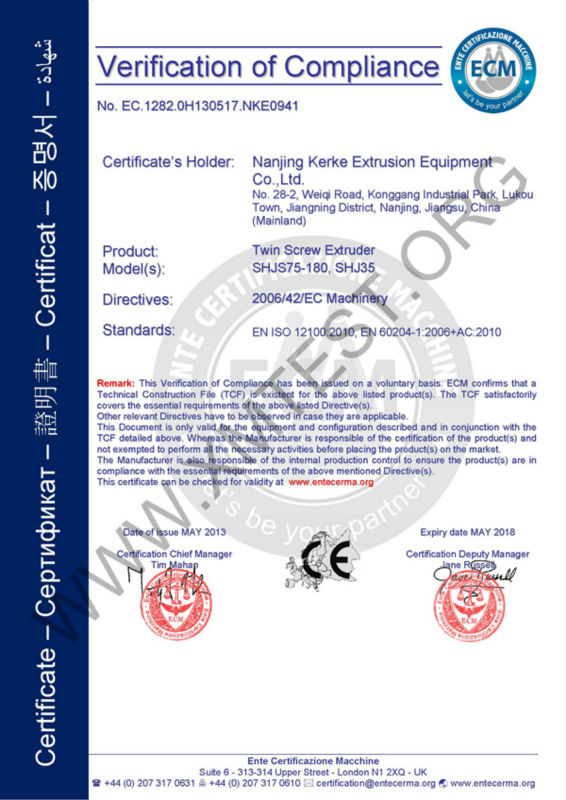

Our professional workers  Certificate

Certificate

Our factory and workshop

Our factory and workshop  Our main products: 1. Co-Rotating Parallel Twin Screw Pelletizing Extruders 2. Single Screw Pelletizing Extruders 3. Die Face Cut (Air Cooling) Pelletizing Extruders 4. Double Stage / Double Degassing Recycling Extruders 5. Crushers, Mixers, Storage Tanks, Vibrators, Granulators, Blowers 6. Extruder spare parts If you interested in our products mentioned above. Kindly let us know by return email. We can supply you the most professional advice according to your demands! Also we can make non-standard plastic machinery as customer’s requirements. Contact: Ms. Lillian Zhu Tel: 0086-25-66096880 Mob:0086-15195826271 Skype:njkerke_lillian Contact us if you need more details on Wpc Granulator. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Two Stage Granulator、Wpc Granulator. If these products fail to match your need, please contact us and we would like to provide relevant information.

Our main products: 1. Co-Rotating Parallel Twin Screw Pelletizing Extruders 2. Single Screw Pelletizing Extruders 3. Die Face Cut (Air Cooling) Pelletizing Extruders 4. Double Stage / Double Degassing Recycling Extruders 5. Crushers, Mixers, Storage Tanks, Vibrators, Granulators, Blowers 6. Extruder spare parts If you interested in our products mentioned above. Kindly let us know by return email. We can supply you the most professional advice according to your demands! Also we can make non-standard plastic machinery as customer’s requirements. Contact: Ms. Lillian Zhu Tel: 0086-25-66096880 Mob:0086-15195826271 Skype:njkerke_lillian Contact us if you need more details on Wpc Granulator. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Two Stage Granulator、Wpc Granulator. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : two stage compounding extruder