New Products

Find Twin-screw Plastic Extruder, Plastic Granules Extruder, Recycled Plastic Machinery on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

| Payment Type: | L/C,T/T |

|---|---|

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 40 Days |

Model No.: SHJ-65B

Model | Screw Diameter D (mm) |

screw L/D |

screw speed N (r/min) | Main motor power P(KW) |

Screw Torque T (N.m) |

Torque Level T/N³ |

Capacity Q(kg/h) |

SHJ20 | 21.7 | 28~40 | 600 | 3/4 | 30 | 4.8 | 3-15 |

SHJ35 | 35.5 | 28~56 | 500 | 11 / 15 | 115 | 4.2 | 20-70 |

SHJ50 | 50.5 | 28~56 | 500 | 45 / 55 / 75 | 425 | 5.1 | 80-150 |

SHJ52B | 51.4 | 28~56 | 400/500/600/800 | 45 / 55 / 75 | 425 | 5.1 | 120-280 |

SHJ65 | 62.4 | 28~56 | 500 / 600 | 55 / 75 / 90 | 675 | 4.8 | 150-300 |

SHJ65B | 62.4 | 28~56 | 400/500/600/800 | 90/110 | 675 | 4.8 | 200-500 |

SHJ75 | 71 | 28~56 | 500 / 600 | 90 /110 /132 | 1005 | 4.6 | 300-550 |

SHJ75B | 71 | 28~56 | 400/500/600/800 | 110 /132/180 | 1005 | 4.6 | 300-700 |

SHJ95 | 93 | 28~56 | 400 / 500 | 250 / 315 | 2815 | 5.9 | 600-1000 |

water-cooling strands pelletizing line >>End products

water-cooling strands pelletizing line >>End products

2.the feeding systerm Various forms of feeding structure and system single screw extruder, twin screw, hollow spring type, mesh and mesh, can cover the various material status

2.the feeding systerm Various forms of feeding structure and system single screw extruder, twin screw, hollow spring type, mesh and mesh, can cover the various material status  3.screw and barrels Screw Kneading block built on modular principle allows various L/D ratio of screw easily be changed to suit different material. Screw component made of high speed & wear-resisting steel. The screw elements are designed accuratly and made of high tool steel 38CrMoALA or W6Mo5Cr4V2 by special heater treatment.

3.screw and barrels Screw Kneading block built on modular principle allows various L/D ratio of screw easily be changed to suit different material. Screw component made of high speed & wear-resisting steel. The screw elements are designed accuratly and made of high tool steel 38CrMoALA or W6Mo5Cr4V2 by special heater treatment.  >>Package and shippment

>>Package and shippment  >> Our professional workers

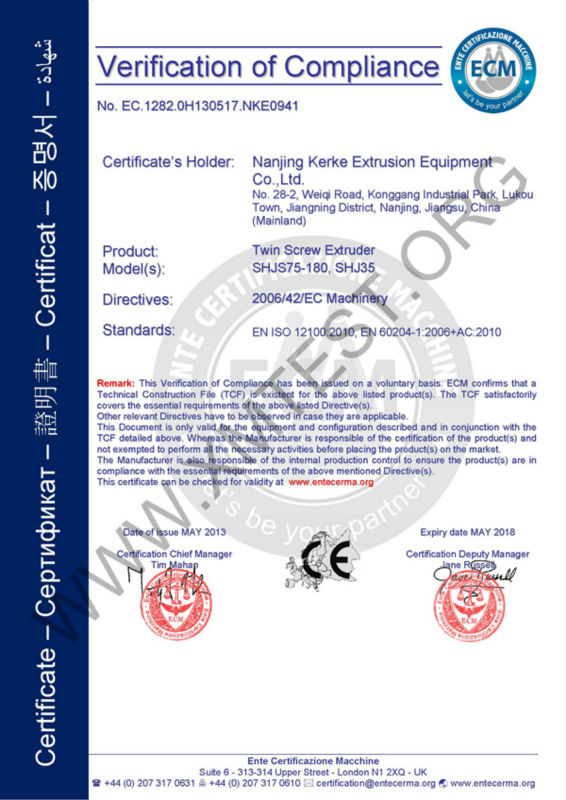

>> Our professional workers >>Certificate

>>Certificate

>>About our factory and workshop

>>About our factory and workshop We are Nanjing Kerke Extrusion Equipment Co., Ltd. our company is a professional manufacturer of high quality pelletizing extruders for coloring /dyeing and masterbatch production, as well as plastic modification and compounding,plastic recycling. The products have been exported to many countries. such as America, Canada, Australia, South Korea, and Southeast Asia, Middle-east, etc . If you interested in our products mentioned above. Kindly let us know by return email! We can provide you the most professional advice according to your demands! Also we can make non-standard plastic machinery as customer’s requirements! Contact us if you need more details on Pet Flake Extruder. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Pet Flake Granulator、Plastic Rigid Granulator. If these products fail to match your need, please contact us and we would like to provide relevant information.

We are Nanjing Kerke Extrusion Equipment Co., Ltd. our company is a professional manufacturer of high quality pelletizing extruders for coloring /dyeing and masterbatch production, as well as plastic modification and compounding,plastic recycling. The products have been exported to many countries. such as America, Canada, Australia, South Korea, and Southeast Asia, Middle-east, etc . If you interested in our products mentioned above. Kindly let us know by return email! We can provide you the most professional advice according to your demands! Also we can make non-standard plastic machinery as customer’s requirements! Contact us if you need more details on Pet Flake Extruder. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Pet Flake Granulator、Plastic Rigid Granulator. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : parallel co-rotating twin screw extruder