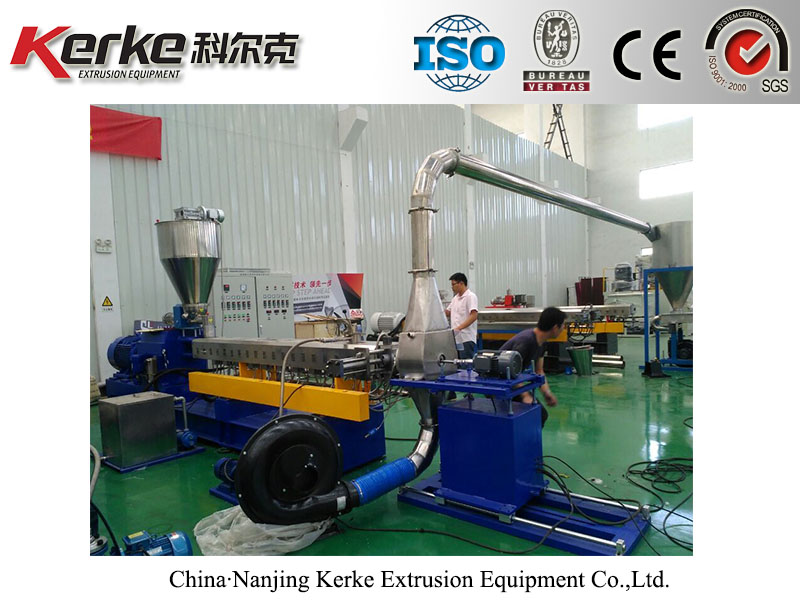

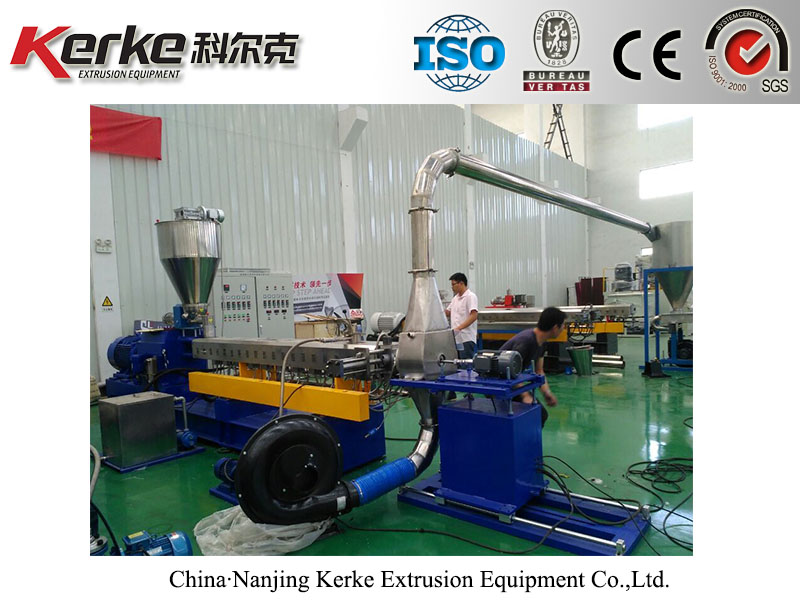

wood pellet making machine wood pellet making machine wood pellet making machine Product Description Functions 1. Reasonable price with high quality 2. CE,ISO certificates 3. Suitable for almost all plastic materials. 4. Polymer material (PP/PE/PET/PVC/ABS ,etc.) 5. Pelletizing system (1) Air-cooling hot-face pelletizer (2) water-ring hot-face pelletizer (3) water-cooling strands pelletizer 6. Professional custom configuration 7. Easy and stable operation Capacity:200~500 kg/h

Main technical parameter:

a) Model: KTE-65B

twin screw extruderb) L/D 40:1;

c) Main motor: 110KW

d) Speed: 60~600rpm;

hot selling professional twin screw wood pellet making machine 1. The pictures of extruder

videos If you are interested in our machines,please wactch the videos for diffierent kinds of plastic pellets production line.

company promotion video https://youtu.be/qt7Mm6CavBo KTE-52B water-ring hot-face https://youtu.be/zPNYb7DFDOA SE-120 sing-screw extruder https://youtu.be/gKhgDKvIerQ KTE-65B air-cooling hot-face https://youtu.be/Q9fCB6uNSFo KTE-52B water-cooling strand https://youtu.be/ZQzWZQrjkl8 KTE-75B air-cooling strand https://youtu.be/4If3i0Mf8mQ KTE-75B water-cooling strand https://youtu.be/ZGlEkU9iER8 2. Product Description of granulator: 1)Twin-screw Air-cooling Hot-face Cutting Pelletizing system:

1.high-speed mixer 2. main feeder 3. side feeder 4. twin-screw extruder 5. water trouh

6.centrifugal off-water machinery 7.vibrating sieve 8. product container Application: 1.PE,EVA etc. ,filled with CaCO3,talc,TiO2,carbon black etc. 2.Cable sheath , cable insulation compounds of LDPE,HDPE,LLDPE,or MDPE; 3.PPR pipe compounds,PE compounds for crosslinked pipes; 4.TPR,TPU TPV thermoplastic elastomers; EVA and hot-melt adhesives 5.Color concentrates of PE,ABS,PS,EVA etc; 6.Flame retardant masterbatcher of ABS,EVA etc; 7.Masterbatches with PE,PP,PS etc. As carriers for degradation applications. Configuration

1.Twin screw Volumetric feeder

2.Reduction gearbox

3.Lubrication oil cooling system

4.Motor of host machine

5.Screw and charging barrel

6.Heating system

7.Vacuum degasification device

8.Soft water cyclic system

9.Screen changer system

10.Auxiliary machine

11.Electrical control cabinet

2)Technical Parameters of twin-screw

color masterbatch extruder:

| Model | Diameter | Length to diameter ration | Speed of screw | Power | Production | Screw torque | Torque grade |

| D (mm) | L/D | N (r/min) | P (KW) | Q (kg/h) | T(N.m) | T/A³ |

| KTE-16A | 15.6 | 28~40 | 600 | 1.1/2.2 | 2~10 | 17 | 5.0 |

| KTE-20A | 21.7 | 28~40 | 600 | 4/5.5 | 3~15 | 86 | 5.2 |

| KTE-36 | A | 35.6 | 28~52 | 500 | 11/15 | 20~60 | 138 | 5.1 |

| B | 35.6 | 28~60 | 500/600 | 18.5/22 | 20~100 | 141 | 5.2 |

| D | 35.6 | 28~60 | 800 | 22/37 | 110~200 | 212 | 7.9 |

| KTE-50 | A | 50.5 | 28~60 | 500 | 45/55/75 | 80~150 | 413 | 5.2 |

| B | 50.5 | 28~60 | 400/500/600 | 45/55/75 | 120~280 | 420 | 5.3 |

| KTE-52 | B | 51.4 | 28~60 | 400/500/600 | 45/55/75 | 120~280 | 420 | 5.3 |

| D | 51.4 | 28~60 | 800 | 55/75 | 225~375 | 430 | 5.4 |

| KTE-65 | A | 62.4 | 28~60 | 500 / 600 | 55 / 75 / 90 | 150~380 | 860 | 6.1 |

| B | 62.4 | 28~60 | 400/500/600 | 90/110 | 200~500 | 825 | 5.9 |

| D | 62.4 | 28~60 | 800 | 110/132 | 350~600 | 1432 | 10.3 |

| KTE-75 | A | 71 | 28~60 | 500 / 600 | 90 /110 /132 | 300~550 | 1210 | 5.6 |

| B | 71 | 28~60 | 400/500/600 | 110/132/160 | 300~800 | 1222 | 5.7 |

| D | 71 | 28~60 | 800 | 160/220 | 500~1000 | 2292 | 10.6 |

| KTE-85B | 81 | 28~60 | 400/500/600 | 160/220/280 | 480~1000 | 2567 | 8.2 |

| KTE-95B | 93 | 28~60 | 400/500/600 | 250 /280/ 315 | 750~1400 | 4202 | 8.9 |

3) advantages: >>This structure can afford a high speed to guarantee highly efficiency >>Easy maintenance >>Its self-cleaning can improve products quality and easy to clean. >>building blocks barrel and screw can afford your variety requirements 4) Spare parts of twin-screw color masterbatch extruder:

1.the gear box 1)rotating speed:MAX 600~1500RPM 2)combining host transmission box speed reduction and torque distribution part together,using three axis style design, with compact structure. Speed reduction, torque distribution and two output shaft radia bearing all use NSK bearings. 3)Gear is 6 grade which is a high precision. High speed overloading hard-tooth surface. The materials are 20CrNi2MoA or 20CrMnMo, HRC 60/62.

2.the feeding systerm Various forms of feeding structure and system single screw extruder, twin screw, hollow spring type, mesh and mesh, can cover the various material status

3.screw and barrels Screw Kneading block built on modular principle allows various L/D ratio of screw easily be changed to suit different material. Screw component made of high speed & wear-resisting steel. The screw elements are designed accuratly and made of high tool steel 38CrMoALA or W6Mo5Cr4V2 by special heater treatment.

Company Information Our machine types: 1. Co-Rotating Parallel Twin Screw Pelletizing Extruders

2. Single Screw Pelletizing Extruders

3. Die Face Cut (Air Cooling) Pelletizing Extruders

4. Double Stage / Double Degassing Recycling Extruders

5. Crushers, Mixers, Storage Tanks, Vibrators, Granulators, Blowers

6. Extruder spare parts

Packaging & Shipping

FAQ

1. Q: Are you a factory or trading company?

----A: Both

2. Q: Where is your factory located? How can I visit there?

-----A: Our factory is located in Nanjing, Jiangsu Province, China,

1) You can fly to Nanjing Airport directly. We will pick you up on Nanjing Lukou International airport;

2) You can fly to Shanghai Pudong International Airport then come to Nanjing by High-speed railway, then we will pick you up in the railway station.

All our clients, from domestic or abroad, are warmly welcome to visit us!

3. Q: What makes you different with others?

----A: 1) Our Excellent Service

For a quick, no hassle quote just send email to us

We promise to reply with a price within 24 hours - sometimes even within the hour.

If you need an advice, just call our export office at +86 025 84938824, we will answer your questions immediately.

2) Our quick manufacturing time

For Normal orders, we will promise to produce within 30 working days.

As a manufacturer, we can ensure the delivery time according to the formal contract.

4. Q: How about the delivery time?

----A: This depends on the product. Typically standard products are delivered within 30 days.

The delivery time of the special products is according to the time of setting up of the tooling.

5. Q: What is the term of payment?

----A: 1) T/T payment; 2) LC;

6. Q: May I know the status of my order?

----A: Yes .We will send you information and photos at different production stage of your order. You will get the latest information in time. contact us If you are interested in our products,please do not hesitate to contact with us.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Contact us if you need more details on Wood Pellet Making Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Twin Screw Wood Pellet Making Machine、Twin Screw Wood Pellet. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : parallel co-rotating twin screw extruder

videos If you are interested in our machines,please wactch the videos for diffierent kinds of plastic pellets production line.

videos If you are interested in our machines,please wactch the videos for diffierent kinds of plastic pellets production line.  1.high-speed mixer 2. main feeder 3. side feeder 4. twin-screw extruder 5. water trouh

1.high-speed mixer 2. main feeder 3. side feeder 4. twin-screw extruder 5. water trouh 2.the feeding systerm Various forms of feeding structure and system single screw extruder, twin screw, hollow spring type, mesh and mesh, can cover the various material status

2.the feeding systerm Various forms of feeding structure and system single screw extruder, twin screw, hollow spring type, mesh and mesh, can cover the various material status  3.screw and barrels Screw Kneading block built on modular principle allows various L/D ratio of screw easily be changed to suit different material. Screw component made of high speed & wear-resisting steel. The screw elements are designed accuratly and made of high tool steel 38CrMoALA or W6Mo5Cr4V2 by special heater treatment.

3.screw and barrels Screw Kneading block built on modular principle allows various L/D ratio of screw easily be changed to suit different material. Screw component made of high speed & wear-resisting steel. The screw elements are designed accuratly and made of high tool steel 38CrMoALA or W6Mo5Cr4V2 by special heater treatment.  Company Information Our machine types: 1. Co-Rotating Parallel Twin Screw Pelletizing Extruders

Company Information Our machine types: 1. Co-Rotating Parallel Twin Screw Pelletizing Extruders